Specifying of technical

documents for production

Specifying of technical documents for production | PEWTRONIC s.r.o.

Here we would like to draw near the mandatory technical documents that the customer should deliver to the production along with the business order. The greater complexity of customer products, the ever-increasing share of machine processing and the rising cost of electronic components make us now more compelled to have a stricter approach to customer documentation. The high standard of the ISO 9001: 2015 system and the application of the IPC-A610 CZ Revision E-2010 for the assessment of electronic assemblies, guarantees customers a clear result in the quality of production, but also undertakes to provide high-quality technical documentation.

Please attention, since January 2020 we are changed format and sizes for full sized stencils to four side stretching system. You will find here its drawing.

Here is a recommendation for the accepted electronic formats of the documents, but we recommend you to study the entire document „Specifications of ELVYR-PEWTRONICsro Technical Data“, which is linked to the terms and conditions:

a) General Accompanying Texts and Guides: Acrobat Reader * .pdf, Microsoft Word * .doc

b) Photos and Special Design Instructions: Picture Formats * .jpg, * .tif, * .bmp

c) Parts lists: We prefer editable versions in Microsoft Excel * .xls or plain text * .txt The reason for this is the additional check with mounting data over the spec script

d) Assembling data: Microsoft excel * .xls or text file * .txt with separating characters not elsewhere in the data (eg semicolon) The data must contain a reference (eg C1), component value, case, X coordinate, Y on the geometric center of the component and the Z rotation. Ideally, the line of the text file with the fitting data may look like: C1; 100n; 0805; 25.425; 12.854; 180

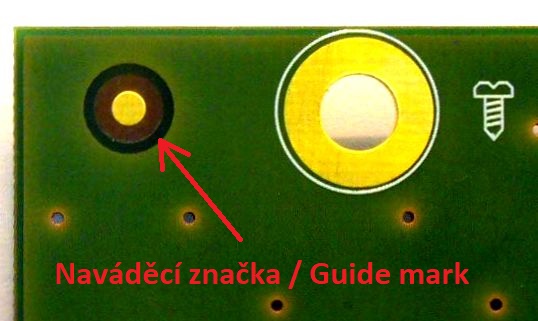

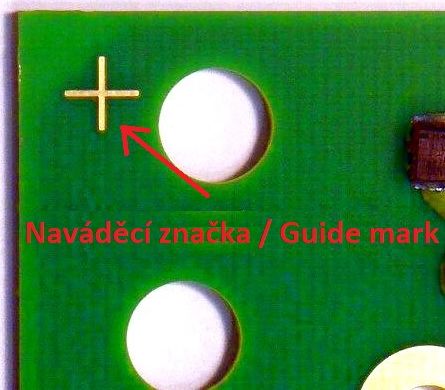

e) Basics for PCB Planet and Production: Gerber Data (GERBER RS 274X), Please do not forget to insert guide marks for automatic machines into layout.

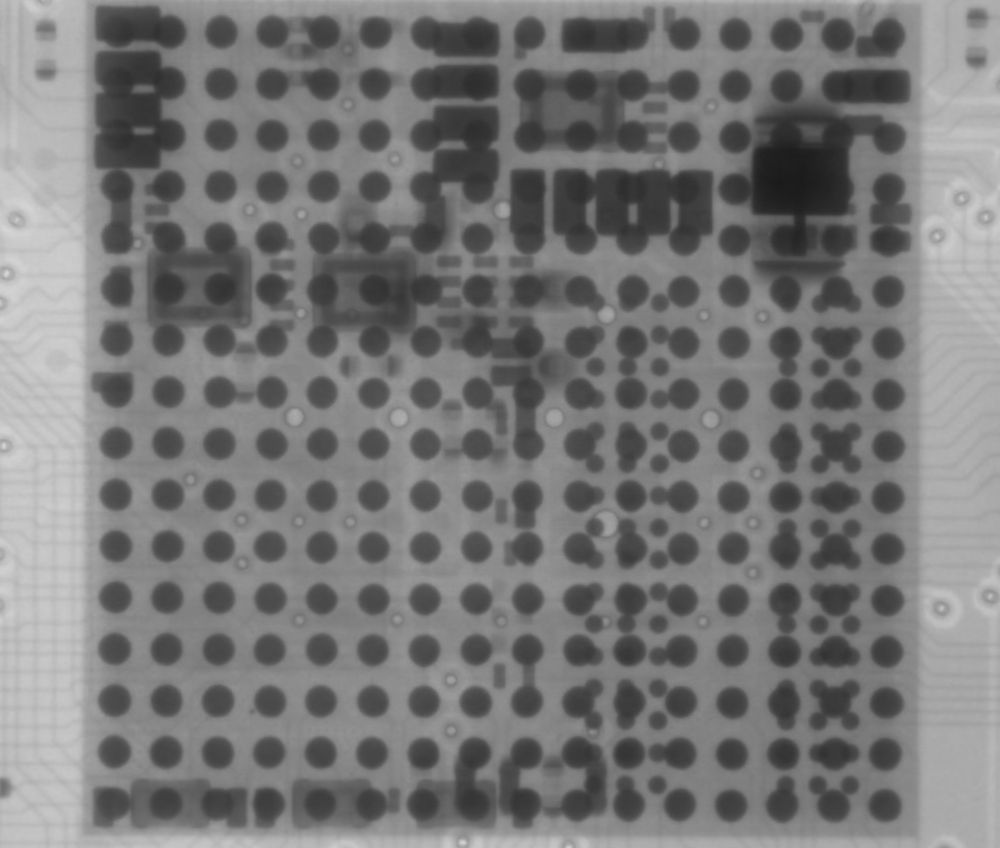

Here you can see short movie taken by placeing machine, where positioning of origin point of the PCB were set up by via (riveting between layers), becouse designer forgot place correct positioning origin points. This mistake affect PCB assembly from begin to end of manufacturing. You can see here fluctuating position of solder pads.

Expected PCB material is FR4, we recommend specifying the thickness. laminate, copper foil and surface treatment.

f) Machine / construction drawings: AutoCad (ProgeCAD) * .dwg

g) A complete project file created in Eagle format * .brd can also be supplied by the customer. From this format, we can generate all the necessary data – embedding data, drawings and gerber data.

h) Documents for PCB conformal coating (painting) should be in the form of two dimensioned drawings fort the TOP and BOT side with the marking of the obligatorily covered part, strictly omitted (unpainted) part of the PCB and the tolerance zone, which will be min. 3 mm wide. The motifs passed in this way will also serve as a qualitative reference for the output visual inspection. We will also be satisfied with a manual drawing in a photo or a text description for simple PCBs, such as „Repaint the entire BOT side, omitting control points M1 to M4“. Of course, the description and indexing must match the PCB drawing provided. Please consider when planning painted zones that the paint is still in a liquid state after application and tends to merge into one unit due to surface phenomena, see. tolerance zone. We can suppress this, but at the cost of auxiliary machinery operations.

Data files should be stored in a single directory that is ideally marked with the product name, version (index od changes), and the date of this documentation release. These directories can be accepted even if the documentation is changed if the directory contains everything you need. Article 3. We also recommend compressing the directory using the compression program in * .rar or * .zip format. You can also encrypt the file and pass it through another feed. Such data sent electronically reduces the risk of misuse of confidential information.

Important note: If harmful viruses are detected in electronic files, the customer will be prompted to re-deliver the complete set of documents!

Last update 18th January 2022

Your certified partner acc. to ISO9001:2015, IPC-A-610 soldering standard and wiring harnesses UL subject 764 CSA. The company PEWTRONIC has great experience since 2003.