Logistics

of projects

Logistics of projects | PEWTRONIC s.r.o.

Project supply is one of our services that greatly saves internal customers resources in the form of time-based costs of making material orders, receipt of material from suppliers, warehouse management and material preparation for production.

In the case of special or customized parts, for which the customer has secured project prizes, or are these in his stock from previous projects, it is obvious, that we will use them for his own products. Terms of acceptance and accounting will be mutually agreed.

We encourage you to read the entire document „Technical specifications of ELVYR-PEWTRONICsro“, which is linked to business conditions.

—

However, if the customer decides to deliver the material himself, he should take the following points as a matter of course:

a) The delivery note for all parts, the marking of the items must be identical to the marking on the packaging of the parts.

b) The supply of all components must be subject to a certain margin which respects the necessary technological loss in relation to the number of components used and taking into account their cost. The actual delivery status must be indicated on the delivery note.

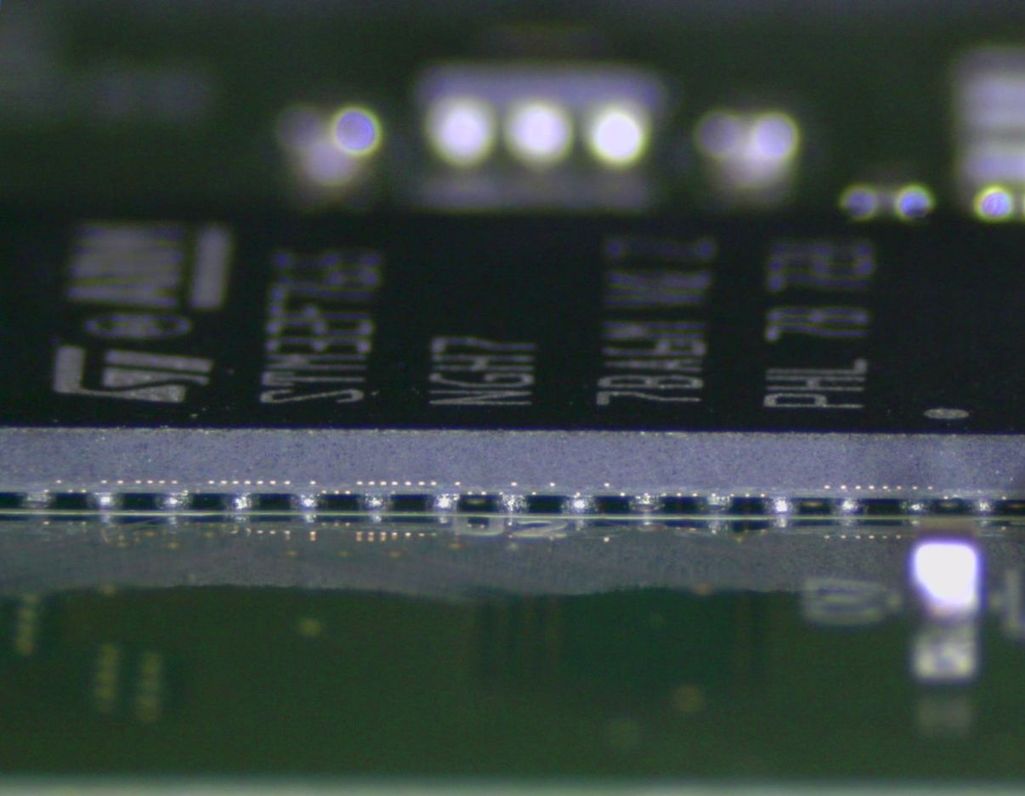

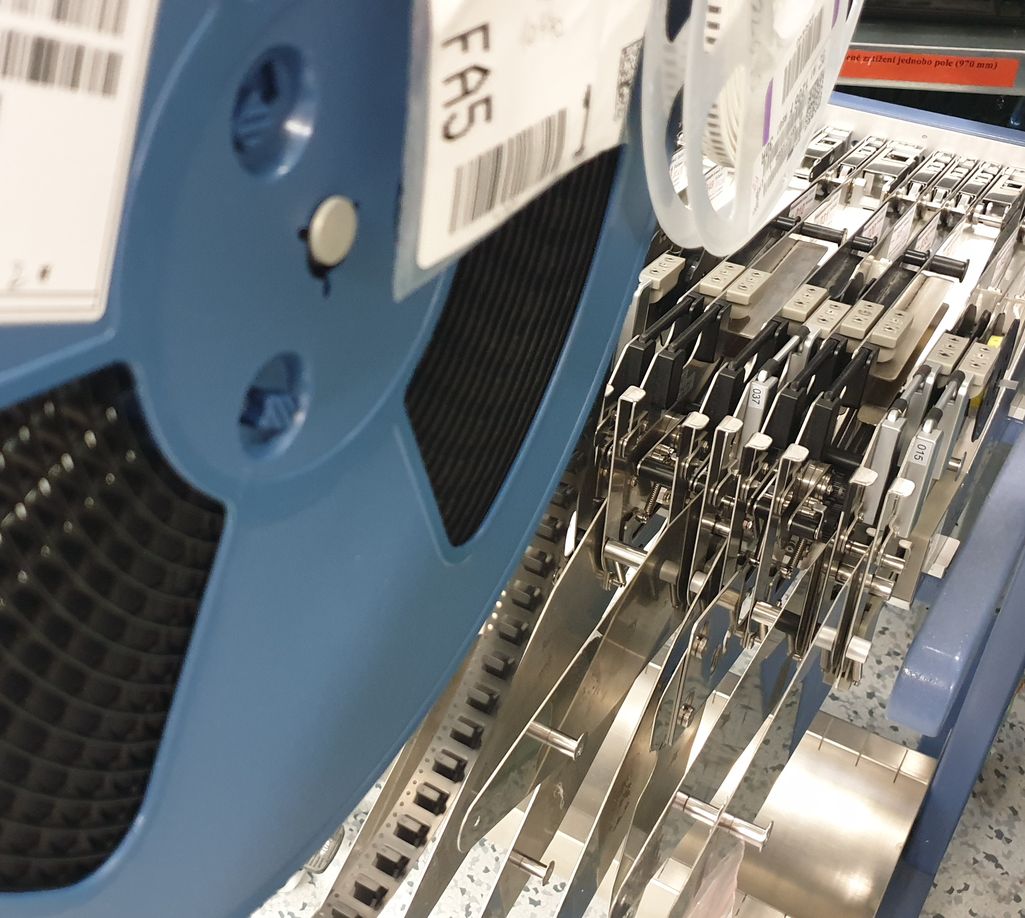

c) SMD components packed in strips must have a portion of the guide and carrier strips so that they can be inserted into the machine feeder without extending. If we have to extend, the time loss is transferred to the customer. Paragraph b) is closely linked to this point.

d) Each component type must come in a single packaging (not on five split bands, etc.) and must comply with paragraph c).

e) Integrated circuits packaged in sticks or „waffles“ shall always be oriented in the same way as in the original packaging.

f) Multi-pin circuits may not have either one deformed state or a state that prevents them from being accurately led to the soldering surfaces. This problem is generally encountered in more expensive parts repackaged from original packaging.

g) The components must be free of surface oxidation, so that their soldering is not impaired.

h) Components must have their origin and compliance with both the ROHS II and REACH directives however, the Pb-free.

i) Electronic components designed for soldering with lead alloy shall be marked and packaged separately.

j) Moisture-proof parts must be packed in hermetically sealed containers or with appropriate moisture inhibitors.

k) Printed circuit boards must always be provided with guide marks! The mark must be a part of the layout, and of both sides of the PCB. Brand shape according to your habits (round target / cross).

l) PCBs must be paneled in frames of approximately A4 size. The maximum size of the processed PCB on the entire line is 310 x 450 mm. The right PCB paneling increases the efficiency of the whole production process!

m) Printed circuit boards must be packed in such a way that they do not damage each other and be oriented in the same way.

n) All packaging materials used must meet the requirements for materials suitable for the packaging of ESD components, may be used in EPAs.

o) In case of customer demands of surplus material inventory, we will reserve the right to charge this service.

p) In the event of damage or extreme technological loss of your material, we will provide compensation, or we will make financial compensation at usual market price.

Last update 22nd February 2024

Your certified partner acc. to ISO9001:2015, IPC-A-610 soldering standard and wiring harnesses UL subject 764 CSA. The company PEWTRONIC has great experience since 2003.